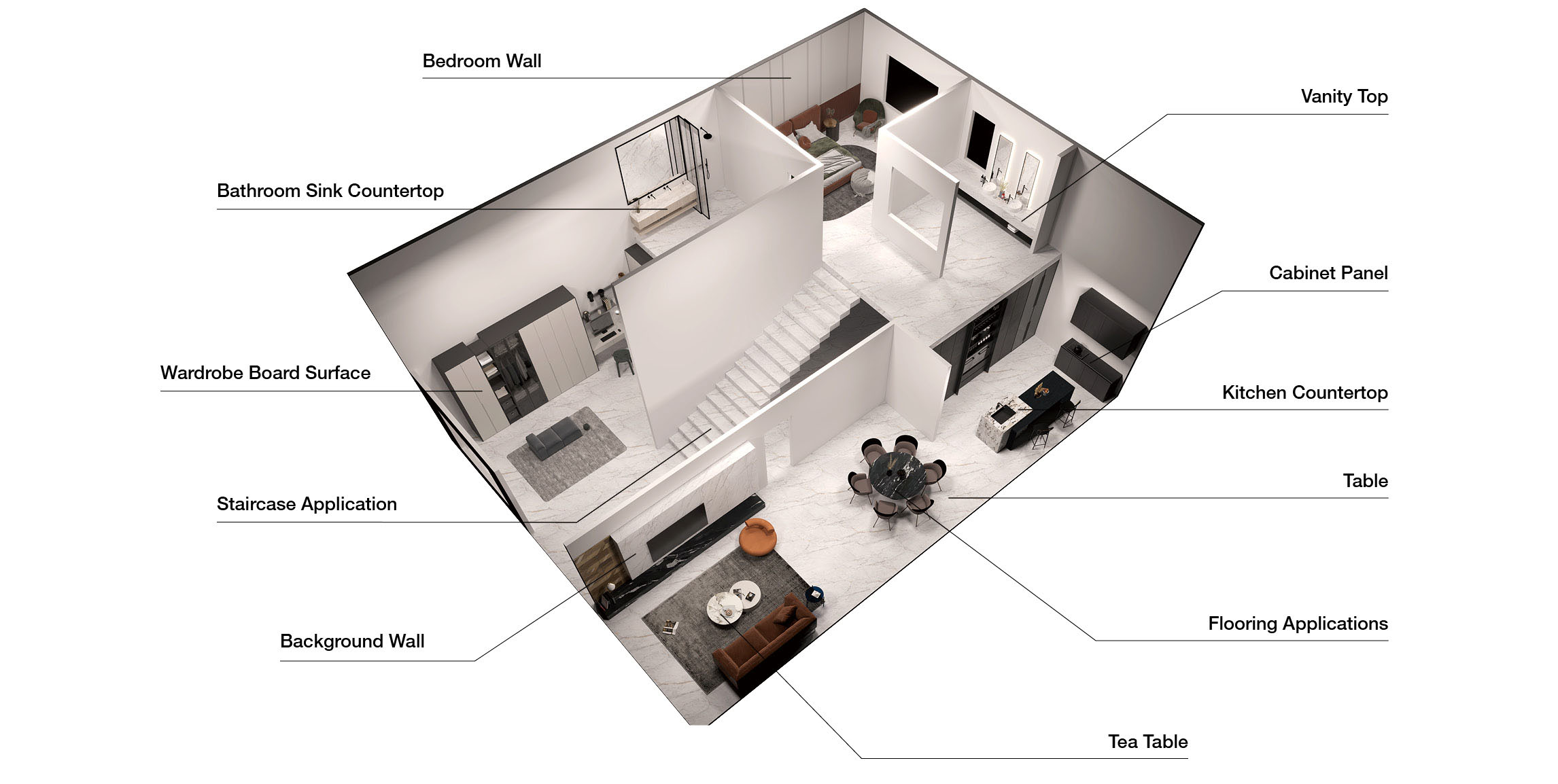

In modern home and commercial design, sintered stone countertops have become a popular choice for kitchens, bathrooms, dining tables, and various countertops. Their high hardness, wear resistance, impermeability, high-temperature resistance, and diverse appearances have attracted increasing consumer attention.

However, in actual use, many people ask: Can sintered stone countertops be polished?

To answer this question, we need to have a deep understanding of the material properties, surface treatment processes, and polishing principles of sintered stone countertops. This article will systematically analyze whether sintered countertops can be polished, and why polishing is generally not recommended.

What is a sintered stone countertop?

Sintered stone countertops are an ultra-dense material made by sintering and pressing natural mineral raw materials (such as quartz, feldspar, and silica) at temperatures exceeding 1200°C and under thousands of tons of pressure. It belongs to the next generation of high-performance artificial stone slabs and has the following key characteristics:

• Extremely hard—Mohs hardness can reach 6-7, resulting in a durable and scratch-resistant surface.

• Nearly zero water absorption—virtually impermeable to liquids, offering strong stain resistance.

• High-temperature resistance—Can withstand direct contact with high-temperature objects without damage.

• Chemical resistance—Resists corrosion from most acids and alkalis.

• Environmentally friendly—Made from natural materials, resin-free and formaldehyde-free.

• Versatile appearance—Can simulate different textures, such as marble, wood grain, and metal.

These characteristics make sintered stone countertops widely used in kitchens, bathrooms, and commercial spaces.

How does polishing work?

Polishing is a surface treatment that continuously refines a material's surface through mechanical friction or chemical action, resulting in a smooth, high-gloss finish. Polishing is commonly used for:

• Natural stone, such as marble and granite → Polishing enhances gloss.

• Wood → Polishing and polishing with oil and wax create a smooth and beautiful surface.

• Metal → Polishing achieves a mirror-like finish.

The core of polishing is to remove subtle surface irregularities, reduce light scattering, and achieve a brighter finish. However, the physical properties of different materials determine whether polishing is feasible and the desired polishing effect.

Can sintered stone countertops be polished?

In theory, sintered stone countertops are extremely hard, making polishing possible. However, in practice, polishing sintered countertops is generally not recommended. The main reasons are as follows:

1. Excessive hardness makes polishing extremely difficult

Sintered stone countertops have a Mohs hardness of 6-7, making them harder than most natural marble. This high hardness makes it difficult for standard polishing equipment and processes to effectively polish the surface. Even if polishing is possible, it is time-consuming and costly, making it extremely inefficient.

2. Surface texture may be damaged

The patterns and colors of sintered stone countertops are formed through the combination of raw materials and the high-temperature sintering process. Polishing may damage the original surface texture, blurring or even eliminating the pattern, thus affecting the overall aesthetic.

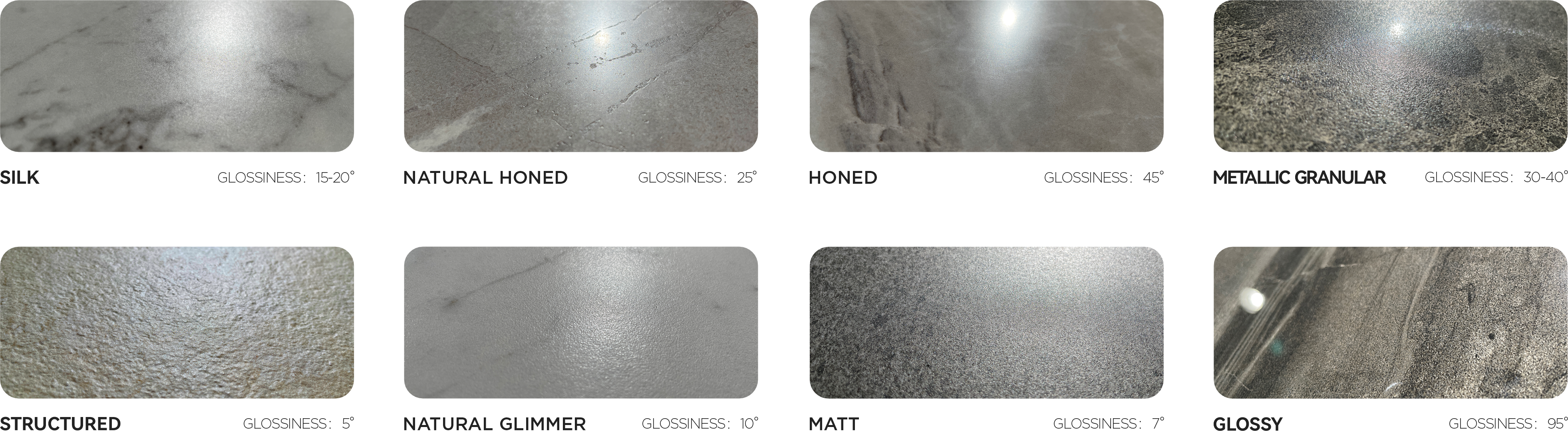

3. Color and gloss may change

The surface finish of sintered stone countertops is often customized at the factory, with the gloss, matte finish, or anti-slip treatment precisely engineered. Polishing alters the original surface condition, causing a lighter color or uneven brightness, which can undermine the overall decorative effect.

4. Reduced Slip Resistance

Some sintered stone countertops have a matte or dry-grained finish to enhance friction and slip resistance. Polishing makes the surface even smoother, reducing the coefficient of friction and increasing the risk of slips during daily use, especially in wet areas like kitchens and bathrooms.

5. Polishing Cannot Repair Intrinsic Defects

If a sintered stone countertop has scratches, cracks, or chipped edges, polishing cannot effectively repair these defects. Due to its extremely dense nature, polishing cannot remove a layer of surface to restore a smooth finish like wood does; instead, it may make defects more noticeable.

Why are sintered stone countertops typically not polished?

In summary, while theoretically, sintered countertops with high hardness can withstand polishing, in practice, the feasibility and practicality of polishing are very low. Therefore, it is generally accepted in the industry that sintered countertops are not suitable for polishing. The root causes can be summarized as follows:

• High hardness leads to low polishing efficiency and high costs.

• Polishing can damage the original pattern and texture of sintered stone countertops.

• Polishing may result in uneven color and surface brightness.

• Polishing can weaken the anti-slip properties of sintered stone countertops, reducing safety.

• Polishing cannot solve practical problems that arise during use.

Therefore, sintered stone countertops are best used in their factory-fresh condition rather than requiring post-polishing to improve or alter their surface finish.

What should I do if my sintered countertop loses its luster?

Although sintered stone countertops are not suitable for polishing, they may lose their luster or appear less than lustrous during daily use. In these cases, the correct approach is not polishing, but the following measures:

1. Daily Cleaning

Keeping sintered stone countertops clean is key to maintaining their luster. Use a neutral detergent and a soft cloth, and avoid using strong acids, alkalis, or cleaning tools with abrasive particles.

2. Clean stains promptly

Coffee, tea, oil, and other stains left on countertops for extended periods can affect their appearance. Wipe them promptly to avoid residue.

3. Use a professional curing agent

There are commercially available curing products specifically for sintered countertops that can help restore the surface's natural luster without requiring aggressive polishing.

4. Avoid improper use

Do not cut, strike, or place extremely hot objects directly on sintered stone countertops to avoid irreversible damage.

Comparing the polishability of sintered countertops with other materials

To better understand why sintered countertops cannot be polished, consider a comparison with other common countertop materials:

• Marble countertops: Softer in texture, they can be polished to restore their luster, but they are susceptible to stains.

• Granite countertops: Harder, but can still be polished with professional equipment.

• Quartz countertops: Smooth in surface, they can be polished to a certain extent, but are limited by their resin content.

• Wood countertops: Easy to polish and buff, but their durability and stain resistance are less.

• Sintered stone countertops: Extremely hard, polishing is almost impossible and will damage the surface finish.

Thus, sintered stone countertops differ significantly from other materials in terms of polishability.

So, can sintered stone countertops be polished?

The answer is: In theory, yes, but in practice, it's rarely feasible and is not recommended.

1. Due to the extreme hardness of sintered stone countertops, polishing is difficult and expensive.

2. Polishing can damage the original texture and color, resulting in an uneven appearance.

3. Polishing may also reduce anti-slip properties, impacting safety.

4. For daily gloss maintenance, the correct approach is cleaning and conditioning, not polishing.

Therefore, when choosing a sintered stone countertop, the best approach is to select the appropriate finish (such as matte, glossy, or non-slip) based on your needs and maintain regular cleaning and maintenance during use. This will preserve the beauty and durability of the sintered countertop while also preventing unnecessary damage.

What makes WOWSLAB a top-rated sintered stone slab supplier?

WOWSLAB is recognized as one of Guangdong’s top ten sintered stone slab manufacturers. Our factory produces premium marble slabs and sintered stone slabs with excellent physical performance and aesthetic appeal.

Our experienced team offers full support from design to installation, ensuring smooth purchasing and project success. By sourcing from WOWSLAB, clients gain access to high-quality slabs from a trusted China-based supplier for residential and commercial projects.