In the high-end home improvement and architectural decoration industries, Sintered Stone Slab is gradually replacing natural marble, quartz, and ceramic tile as an innovative surface material that combines beauty and performance.

However, there remains much controversy regarding its installation and maintenance methods. One of the most frequently asked questions is: Does Sintered Stone Slab need to be sealed?

Many people confuse Sintered Stone Slab with natural stone, assuming that all "stone" materials require sealing after installation. However, the physical structure of Sintered Stone Slab is fundamentally different from that of traditional stone.

This article will analyze this issue in depth from multiple perspectives, including material composition, surface characteristics, installation techniques, and maintenance details, to help you correctly understand the relationship between sealing and Sintered Stone Slab.

Why is Sintered Stone Slab mistakenly believed to require sealing?

1. What is Sintered Stone Slab?

Sintered Stone Slab is a dense slab made from natural minerals through high-temperature and high-pressure sintering.

The production process involves using tens of thousands of tons of pressure to compress mineral powders, including quartz, feldspar, silica, and natural pigments, into a compacted form. The powders are then sintered at temperatures exceeding 1200°C, causing the minerals to restructure and form a crystal structure similar to natural rock.

This means that Sintered Stone Slab is not a coating or composite material, but rather a true "artificial rock" with a density and hardness exceeding even most natural marble.

2. Why is it mistakenly believed to require sealing?

The main reason is that the concept of "stone" is often associated with being porous and absorbent.

Traditional natural stones, such as marble and granite, contain pores invisible to the naked eye, allowing liquids and stains to easily penetrate. Therefore, natural stone typically requires waterproofing and sealing after installation.

While Sintered Stone Slab may appear similar to stone, its water absorption rate is extremely low (typically less than 0.1%), meaning it has virtually no ability to absorb liquids.

The structure of sintered stone slab determines whether it requires sealing.

Sintered Stone Slab's Density and Waterproofing

The biggest difference between sintered stone slab and natural stone lies in its density.

During the sintering process, the mineral particles fuse together at high temperatures, forming a dense structure with virtually no pores. This structure exhibits the following characteristics:

1. Water Absorption Rate: Less than 0.05%

Sintered stone slab's water absorption rate is significantly lower than that of granite (approximately 0.3%-0.5%) and marble (1%-2%), making it a material that absorbs virtually no water.

2. High Surface Stain Resistance

Sintered stone slab's surface is sintered at high temperatures and mechanically polished, making it impervious to liquids such as oil, red wine, and coffee, and can be cleaned with a simple wipe.

3. High Chemical Resistance

Sintered stone slab is resistant to common acids and alkalis (such as lemon juice and detergents) and will not corrode.

Because of this, the impermeability of sintered stone slab is inherent to the material and does not rely on sealants.

Does sintered stone slab require sealing? — Generally not

1. No sealing required for general interior applications

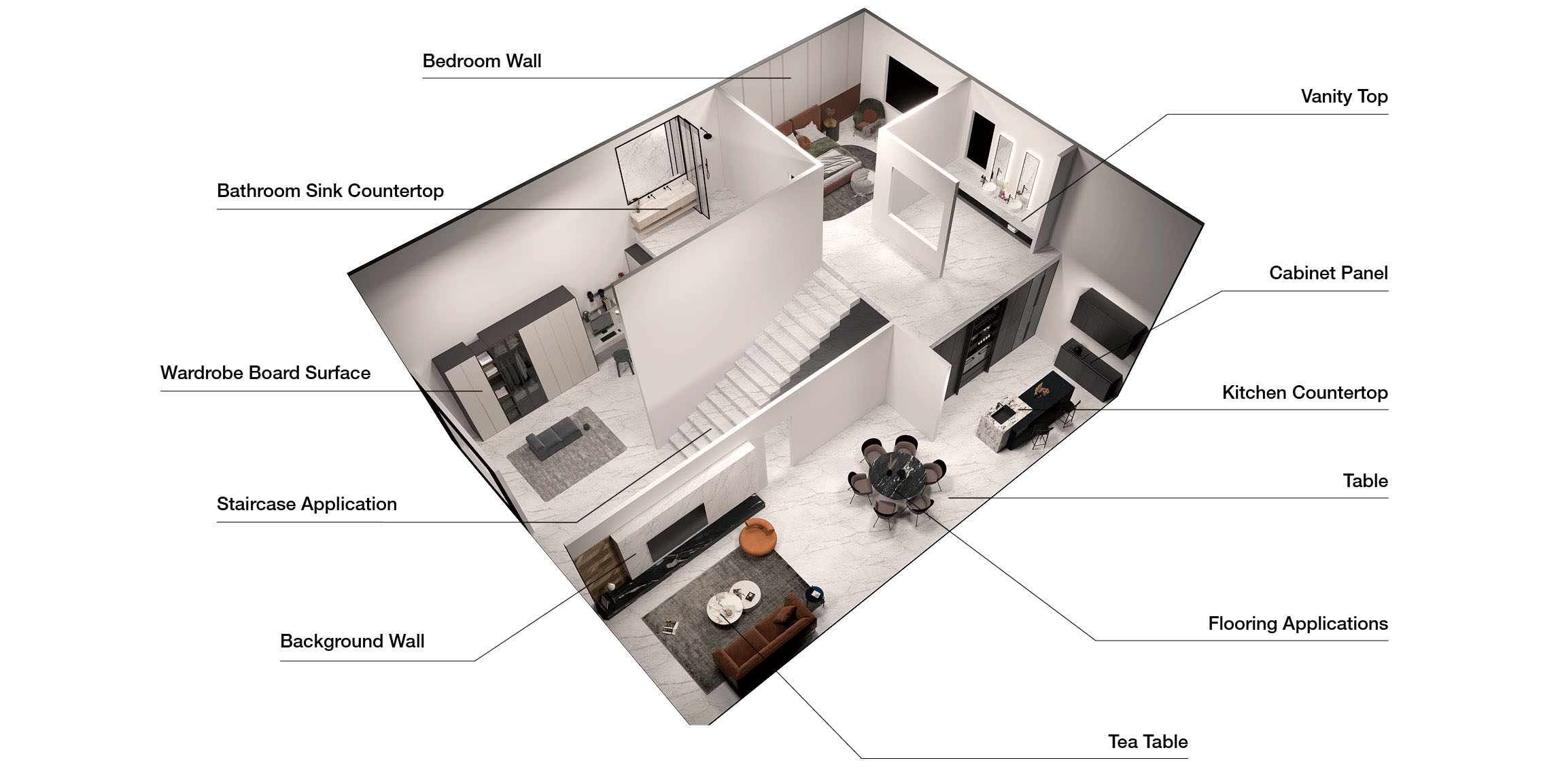

For most indoor applications, such as floors, walls, kitchen countertops, and bathrooms, sintered stone slab does not require sealing at all.

Its waterproof and stain-resistant properties stem from its inherent structure, not from a surface coating.

Unlike natural marble, sintered stone slab remains stable, resists stain absorption, and does not discolor even after prolonged exposure to moisture, oil smoke, or detergents.

2. The visual appearance does not affect the protective effect

Sintered stone slab comes in a variety of finishes, including polished, matte, rock, and silk.

Regardless of the finish, its impermeability is determined by the sintering density, not the surface gloss. In other words, matte sintered stone slab does not require sealing; its water resistance is virtually identical to that of glossy slab.

What special circumstances warrant sealing?

While sintered stone slabs generally don't require sealing, localized sealing may be beneficial under certain construction or environmental conditions. The following situations are for reference:

1. Exposed Cut Edges

When sintered stone slabs are cut or edged, some of their microporous structure may be exposed on the cut surface.

If these edges are used in high-humidity environments, such as around kitchen sinks or on the edges of sinks, it's recommended to apply a layer of transparent protective agent to prevent soiled water from seeping through.

2. Seepage Protection of Joints

Sintered stone slabs often use caulk or structural adhesive in their joints, which may absorb water or stain more easily than the slab itself.

Therefore, sealing should focus on the joints, not the slab itself. Using a specialized waterproof caulk and applying a spray sealant after curing can effectively prevent the joints from discoloring or mold.

3. Outdoor Environments or Commercial Spaces

When sintered stone slabs are used for outdoor floors or building exteriors, where they are exposed to rain, dust, UV rays, and temperature fluctuations for extended periods, a special protective film can be applied to the surface to enhance their stain and aging resistance.

This protection is a physical barrier, not a traditional permeable seal.

4. Special Textured or Rough Surfaces

Some sintered stone slabs utilize a rock or sand finish, resulting in a fine, uneven surface texture. While still impermeable overall, dirt may adhere to the texture. Appropriate use of a nano-scale antifouling agent can reduce surface adhesion and ease cleaning.

Suitability of Sealant for Sintered Stone Slabs

1. Can traditional stone sealants be used on sintered stone slabs?

Traditional marble and granite sealants are primarily penetrating formulas, working by penetrating the pores of the stone to form an impermeable layer.

However, since sintered stone slabs are virtually non-porous, these products are difficult to penetrate and cannot form an effective protective film.

On the contrary, excessive use may cause the surface to become white, sticky, or lose its gloss.

Therefore, if protection is absolutely necessary, choose a non-penetrating protective agent specifically formulated for sintered stone slab surfaces, such as:

• Fluorocarbon polymer protective agents

• Nanosiloxane antifouling agents

• Inorganic waterproof coatings designed for ceramic or ultra-compact surfaces

These products form an ultra-thin protective film on the surface, increasing stain resistance without affecting breathability or appearance.

Scientific Process and Key Points for Protecting Sintered Stone Slab Installation

Sealing is not the only factor affecting anti-seepage. The construction method used during the sintered stone slab installation process is equally critical to the final result.

The following points can ensure that sintered stone slab maintains its excellent anti-seepage performance even without sealing:

1. Surface Preparation

Ensure that the floor or wall surface is clean, dry, and dust-free. High moisture content in the substrate may cause adhesive failure or alkali reaction.

2. Use Special Tile Adhesive or Epoxy Adhesive

Sintered Stone Slab is heavy and dense, so it is recommended to use C2TES Grade 1 or higher tile adhesive or epoxy adhesive to ensure a secure bond.

3. Maintain Expansion Joints

When laying large areas, expansion joints should be provided to accommodate micro-expansion caused by temperature fluctuations and prevent bulging or cracking of the slab.

4. Joint Filling and Waterproofing

Use a mildew-resistant epoxy caulking agent or polyurethane waterproof adhesive to fill the joints. After caulking, lightly brush sealant over the gaps for additional protection.

5. Cleaning After Installation

Immediately clean any residual adhesive, grout, or dust from the surface after installation to prevent permanent stains from drying.

These construction tips, more than sealing itself, determine the lifespan and appearance stability of the sintered stone slab.

Daily Maintenance of Sintered Stone Slab After Installation

1. How to Keep Unsealed Sintered Stone Slab Clean?

Even if unsealed, sintered stone slabs are very easy to maintain. Here are the key steps to keep it looking new for a long time:

• Daily Cleaning: Use warm water or a neutral detergent. Avoid strong acids, strong bases, or chemical cleaners containing fluoride.

• Degreasing: For sintered stone slabs in kitchen areas, use a kitchen grease cleaner. Spray it on and let it sit for a few minutes before wiping it clean.

• Preventing prolonged water accumulation: Although sintered stone slabs do not absorb water, accumulated water can cause mold in the joints. Maintaining ventilation and drying is recommended.

• Avoiding Wax Coatings: Do not wax sintered stone slabs, as wax can clog the pores and cause uneven gloss.

• Regularly Inspect Joints: Check the caulking annually for signs of deterioration or flaking. Repair any damage promptly.

Due to its high density, sintered stone slabs require little to no maintenance when used properly and will remain resistant to fading and staining for decades.

Potential Problems of Improper Sealing

Many consumers blindly seal without understanding the material's properties, which can lead to negative consequences:

• Surface discoloration or loss of gloss: Sealant forms a white, hazy film on impermeable surfaces.

• Sticky or slippery feel: Some waxy sealants can make the surface slippery, making it unsuitable for flooring.

• Difficulty in cleaning: The film formed on the surface makes dirt more susceptible to adhesion and difficult to remove.

• Significant color difference: Some sealants react with mineral pigments, causing color differences or darkening.

Therefore, before using a sealant, be sure to confirm that it is suitable for sintered stone slabs and test it on a sample first.

Does sintered stone slabs need sealing?

In most cases, sintered stone slabs do not require sealing:

• Sintered stone slabs' impermeability and stain resistance stem from their highly dense structure;

• No additional sealing is required for interior walls and floors, kitchen countertops, or bathrooms;

• Partial sealing may be optional in special circumstances (cut edges, outdoor areas, or rough surfaces);

• If sealing is necessary, use a non-permeable, stain-resistant product;

• Proper application, proper caulking, and regular cleaning are more critical than sealing.

Sintered stone slabs are a high-performance material with virtually zero water absorption and are naturally impermeable. Sealing is not a required step, but rather an optional supplemental measure.

How does WOWSLAB maintain quality control for every order?

WOWSLAB implements strict quality control measures in our China-based factory to ensure every marble and sintered stone slab meets high standards. Buyers can place wholesale, bulk, or customized orders with confidence. We offer competitive pricing, promotional discounts, and detailed quotes.

Our professional team provides design consultation, installation guidance, and after-sales support. By purchasing from WOWSLAB, clients secure high-quality, durable, and visually appealing stone slabs from a trusted global supplier.