The term "Sintered Slab" is increasingly common in modern architecture and home design. Widely used in kitchen countertops, floors, walls, and even furniture finishes, it's a favorite among designers and consumers for its refined appearance and superior performance.

However, many people, upon first hearing the term "Sintered Stone Slab," wonder: Is Sintered Stone Slab fake stone? How does it differ from natural stone? Is it simply a processed "imitation"?

This article will systematically and professionally address these questions from multiple perspectives, including its material structure, manufacturing process, performance characteristics, and applications, to help you fully understand the true nature of Sintered Slab.

What exactly is Sintered Stone Slab?

Sintered Stone Slab is not simply "fake stone" in the truest sense; it is a high-performance artificial rock slab manufactured through a high-tech process.

It is formed by sintering natural mineral raw materials (such as quartz powder, feldspar, silica, and natural clay) at temperatures exceeding 1200°C under high pressure. This process closely resembles the geological processes that naturally form rocks in the Earth's crust. Therefore, the internal structure, density, and stability of sintered slab closely resemble those of natural rock.

In other words, although sintered stone slab is "artificially manufactured," its composition and formation mechanism are derived from the high-temperature lithification process of natural minerals. It is not a low-quality imitation of "fake stone."

Differences between Sintered Stone Slab and Natural Stone

Item | Sintered Stone Slab | Natural stone |

| Main Ingredients | Natural mineral powder sintered at high temperatures | Naturally formed rock |

| Manufacturing Method | Industrial sintering (manually controlled) | Naturally formed (uncontrollable) |

| Density and Hardness | Higher, more stable | Contains natural cracks and pores |

| Water Absorption | Nearly zero | High (especially marble) |

| Stain Resistance | Extremely strong | Permeable, requires regular waxing |

| Dimensions and Thickness | Can be customized for large areas | Subject to natural mining restrictions |

| Environmental Safety | No radiation, no heavy metals | Some stones contain radioactive elements |

As can be seen in the table, the "artificial" nature of sintered slab does not mean "fake." On the contrary, it is a scientifically optimized, authentic mineral slab that even surpasses natural stone in structure and performance.

Why do many people mistakenly believe sintered stone slab is fake?

Although sintered stone slab's material is naturally derived, its manufacturing process is completely controlled by humans, leading to misunderstandings among consumers. The following are several key reasons for this misunderstanding.

1. "Artificial" can easily be misunderstood as "imitation."

"Sintered Stone Slab" falls under the broad category of "artificial stone," but it's completely different from traditional artificial stone (such as acrylic or quartz). Traditional artificial stone is typically made by mixing resin with stone powder, while Sintered Slab contains no resin at all. It's made by physically sintering pure minerals at high temperatures, making it a "physically sintered stone" rather than a "chemically bonded stone."

2. Its appearance can mimic natural stone textures

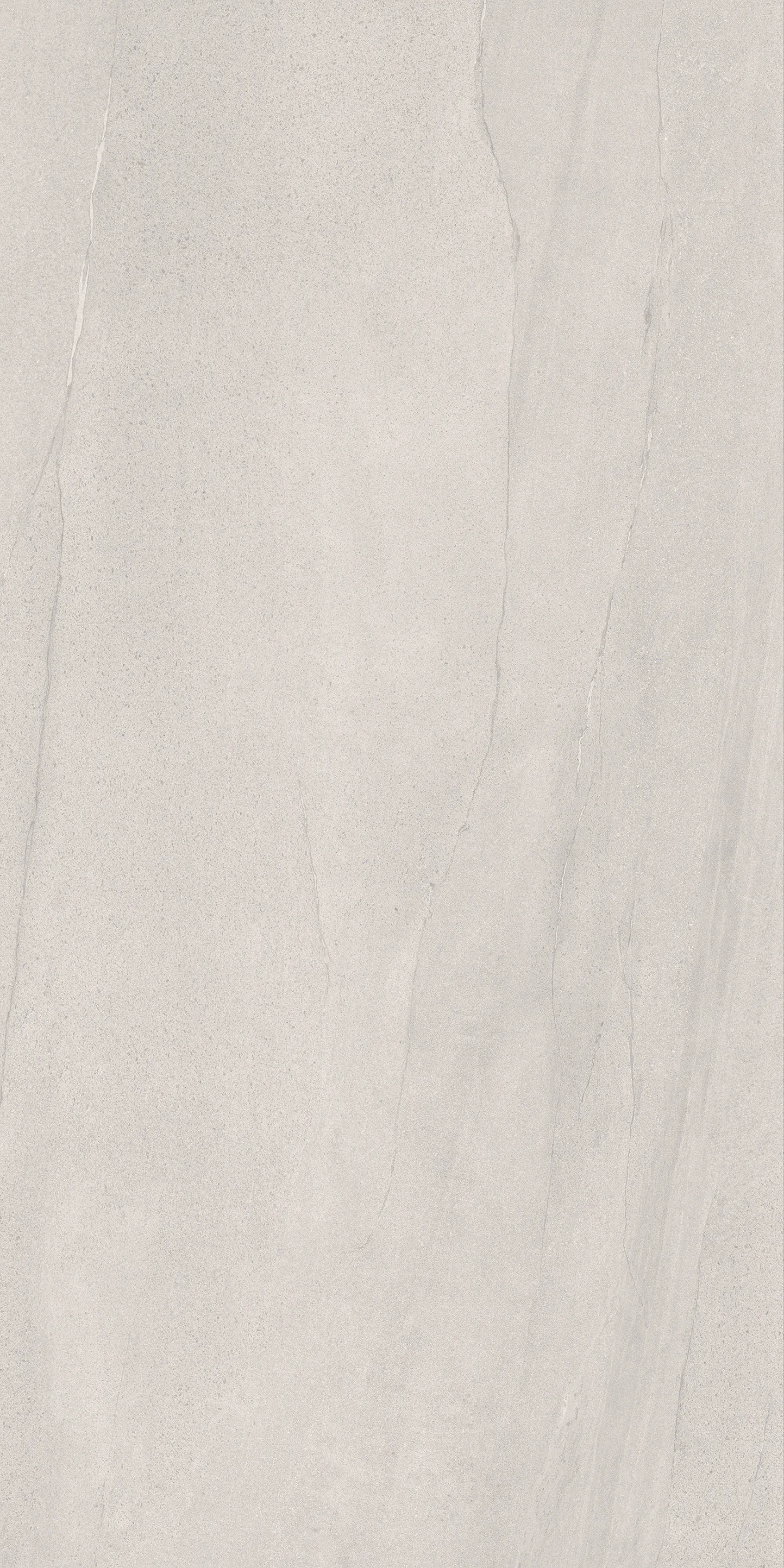

Sintered Stone Slab can be designed to closely resemble natural stone patterns, such as marble and slate. Because of its highly realistic visual effect, some people mistakenly believe it's "imitation stone" or "veneer stone." However, its patterns are actually formed directly into the slab through a high-temperature sintering process, rather than printed on the surface.

3. Confusion among "quartz stone," "rock slab," and "porcelain slab."

Terms like "rock slab," "porcelain slab," "sintered slab," and "quartz stone" are frequently used interchangeably in the market, making it difficult for many consumers to distinguish. In reality, "Sintered Slab" is a high-end slab with a higher technical threshold and superior overall performance, completely different from conventional "ceramic tiles" or "quartz stone."

Is the manufacturing process of Sintered Slab the core essence of real stone?

To determine whether Sintered Slab is "fake stone," the key is to determine whether its manufacturing process faithfully reproduces the rock formation process.

The production process of Sintered Slab includes the following steps:

• Raw material selection and proportioning: High-purity mineral powders such as natural quartz, feldspar, and alumina are selected.

• Ultra-high-pressure pressing: Slabs are pressed into slabs using 10,000-ton-capacity press equipment to ensure uniform density.

• High-temperature sintering: Sintering at temperatures exceeding 1200°C fuses the mineral particles together.

• Cooling and shaping: Natural cooling and mechanical shaping stabilize the internal structure of the slab.

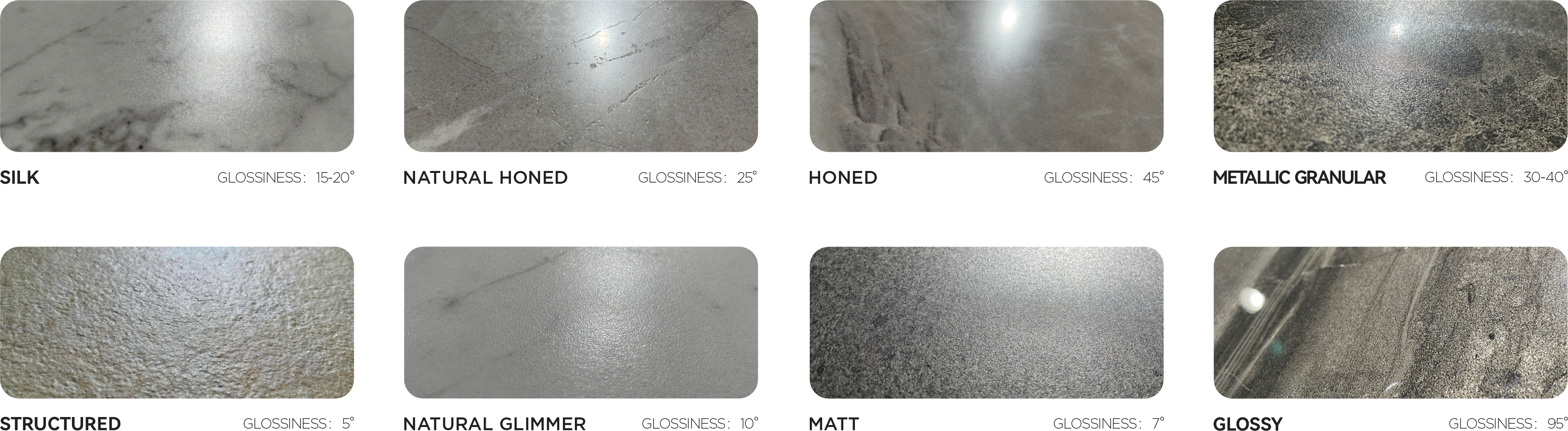

• Fine grinding and polishing: The surface undergoes multiple grinding steps to achieve different gloss effects.

This process is highly similar to the formation of rocks deep within the Earth's crust, except that millions of years of natural processes are compressed into a few hours of industrial processing.

Thus, from a physical perspective, Sintered Stone Slab is not "fake stone" but rather an "accelerated version of natural stone."

What are the performance advantages of Sintered Slab, a genuine material?

If the value of natural stone lies in its "natural beauty," then the value of Sintered Slab lies in its "scientific authenticity."

1. Ultra-low water absorption

Sintered Stone Slab typically absorbs less than 0.05%, far less than marble or granite. This means it absorbs virtually no moisture, oil, or pigment, making it ideal for use in humid spaces like kitchens and bathrooms.

2. High hardness and scratch resistance

With a Mohs hardness of 6-7, it's difficult to scratch with a knife. In comparison, marble, with a hardness of only 3-4, is easily scratched.

3. High-Temperature and Thermal Shock Resistance

Sintered Stone Slab can withstand temperatures exceeding 1000°C and will not deform or discolor from direct contact with hot pans, making it ideal for kitchen countertops.

4. Acid and Alkali Resistance and Corrosion Resistance

Due to its dense crystal structure, Sintered Slab effectively resists corrosion from acids, alkalis, alcohol, detergents, and other chemicals, maintaining a long-lasting, pristine surface finish.

5. Environmentally Friendly and Radiation-Free

Sintered Stone Slab contains no resins or heavy metals, and does not emit radioactive elements. It meets international environmental standards and is a safe and healthy building and decorative material.

These properties are not "imitations" but rather derive from the physical structure and natural mineral composition of Sintered Slab, further proving its authenticity.

How does Sintered Slab differ from other "artificial stones"?

Many people confuse Sintered Slab with quartz and artificial marble, believing them to be "fake stones." In reality, there are fundamental differences between them:

Comparison Items | Sintered Stone Slab | Quartz stone | Artificial marble |

| Main Ingredients | Natural mineral powder (resin-free) | Quartz powder + resin | Calcium carbonate + resin |

| Manufacturing Process | High-pressure, high-temperature sintering | Curing by pressing at room temperature | Casting and curing at room temperature |

| High Temperature Resistance | Resistant to 1000°C | Approximately 150°C | Easily deformed |

| Environmental Performance | Formaldehyde-free, radiation-free | Smells of resin | May release VOCs |

| Appearance Stability | Permanently discolored | May turn yellow with long-term use | Susceptible to aging and cracking |

Sintered Stone Slab, a genuine material slab based on natural minerals and formed through a high-temperature physical process, is significantly superior to ordinary "artificial stone" in terms of performance and environmental friendliness.

From a professional perspective: Is Sintered Slab fake stone?

Judging from its chemical composition, physical structure, manufacturing principles, and performance characteristics, Sintered Slab is not fake stone, but rather a technologically optimized form of genuine stone.

Its artificial nature is reflected only in its manufacturing method, not in its inherent material properties. If natural stone is "a work of nature," then Sintered Stone Slab is "nature recreated through technology."

For this reason, many high-end architectural and design projects have chosen Sintered Slab as an alternative to natural stone. It not only retains the beauty of natural stone but also addresses its shortcomings of cracking, permeability, and maintenance difficulties.

Sintered Slab's Applications Demonstrate Authenticity

Sintered Slab is widely used in a variety of applications, including floors, walls, kitchen countertops, sinks, and furniture finishes, precisely because it possesses authentic and reliable physical properties. If it were truly "fake," it would simply not be able to withstand long-term use in these demanding environments.

For example:

• Kitchen countertops: Heat-resistant, scratch-resistant, and stain-resistant.

• Bathrooms: Moisture-resistant, mildew-resistant, and resistant to detergents.

• Exterior wall decoration: UV-resistant, weather-resistant, and colorfast.

The stability of these properties proves that Sintered Slab is not a counterfeit material, but a new type of high-performance genuine stone slab.

Can I request quotes for large-scale marble slab projects?

Yes. WOWSLAB specializes in providing detailed quotes for large-scale marble and sintered slab projects. Our factory in China produces high-quality slabs suitable for wholesale and bulk purchasing. Buyers can request customized sizes, designs, and finishes, while enjoying competitive prices and promotional offers.

Our professional team provides guidance throughout every step of the project, including design consultation, installation instructions, and after-sales service. Buying from WOWSLAB ensures premium-quality slabs with reliable support for large projects.