In modern home renovations and commercial space design, the choice of countertops and decorative materials not only impacts the aesthetics of the space but also its durability and maintenance costs. Among the many materials available, imitation marble slabs and sintered stone slabs have attracted considerable attention due to their unique properties. Both materials are widely used in kitchen countertops, bathroom sinks, floor coverings, wall cladding, and furniture finishes.

When faced with the question, "Imitation marble vs. sintered stone: Which is better?", many consumers still struggle to decide. This article will provide a comprehensive analysis from multiple perspectives, including definition, production process, performance characteristics, aesthetic effects, application scenarios, maintenance, and cost-effectiveness, providing professional reference.

What is imitation marble slab?

1. Definition of imitation marble slab

Imitation marble slab is a decorative material that artificially simulates the texture, color, and feel of natural marble. It is typically made from quartz sand, resin, natural stone powder, cement-based materials, or a ceramic substrate. Processes such as printing, lamination, pressing, and polishing create a smooth slab. Its primary purpose is to provide a visual effect close to that of natural marble while reducing costs and addressing the scarcity of natural marble.

2. Key Features of Imitation Marble Slabs

• Highly Authentic Appearance: Imitation marble slabs can mimic the textures of a variety of classic marbles, such as Calacatta, Jazz White, and Fish Belly White, with clear grain and a variety of colors.

• Controllable Grain: The pattern and color can be manipulated during the production process, ensuring a consistent texture over large areas and avoiding the coordination difficulties associated with the random grain of natural marble.

• Relatively Affordable: Imitation marble slabs are made of synthetic materials and have low production costs, making them an economical choice for aesthetically pleasing homes or commercial spaces.

• Average Physical Properties: Imitation marble slabs are inferior to natural stone in terms of hardness, wear resistance, and high-temperature resistance. They are prone to scratches and heat marks during use and require maintenance.

• Lightweight: Compared to natural marble, imitation marble slabs have a lower density, making them easier to install and suitable for non-load-bearing applications such as wall coverings and furniture finishes.

3. Applications of Imitation Marble Slabs

Imitation marble slabs are commonly used for:

• Background walls, TV walls, decorative facades

• Home cabinet countertops and small countertops

• Light decoration in commercial spaces

• Spaces with a limited budget that desire the visual effect of marble

Although imitation marble slabs resemble natural stone in visual appearance, they have certain limitations in functionality and durability, requiring careful selection based on the intended use.

What is sintered slab?

1. Definition of sintered slabs

Sintered slabs are a high-end decorative material composed of natural quartz, feldspar, clay, and mineral pigments. They are produced through high-temperature sintering (above 1200°C) and high-pressure pressing (10,000 tons). Their core advantage lies in their extremely dense internal structure and translucent surface patterns that resist wear and tear even with long-term use. Sintered slabs combine the texture of natural stone with the stability of industrial materials and are widely used in high-end homes and public spaces.

2. Characteristics of Sintered Stone

• High Hardness: With a Mohs hardness rating of 6 or higher, it offers excellent scratch and pressure resistance, making it an ideal material for high-intensity environments such as kitchen countertops and dining tables.

• High-Temperature Resistance: Sintered stone can withstand high temperatures and will not be damaged by direct contact with hot pots or open flames.

• Stain and Penetration Resistance: With a near-zero water absorption rate, it is impervious to liquids like oil, sauce, and coffee, making it easy to clean daily.

• Environmentally Friendly and Healthy: Made from natural, inorganic materials, it contains no added resins or harmful substances and is suitable for direct contact with food.

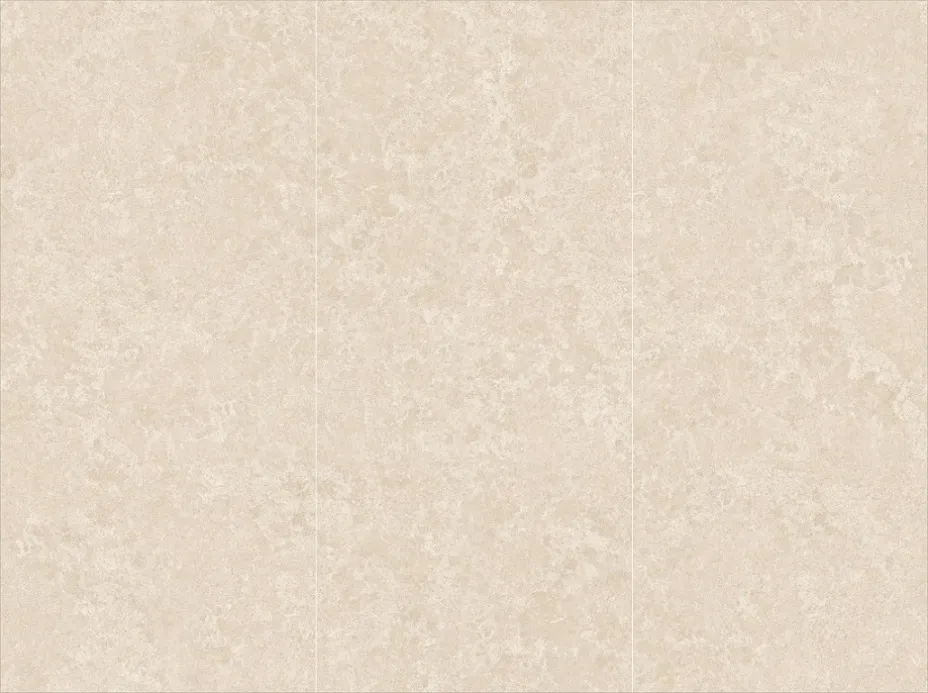

• Elegant and Beautiful: A variety of effects can be achieved, including marble, wood grain, cement texture, and metallic texture, offering flexible design options.

• Long Lifespan: Sintered stone retains its shape and color for decades, requiring virtually no special maintenance.

3. Applications of Sintered Slate

Sintered slate has a wide range of applications:

• Kitchen countertops, dining tabletops

• Bathroom sinks, vanities

• Public space floors and walls

• Outdoor decoration and high-end home furnishings

It not only combines aesthetic appeal with high durability and functionality.

Imitation Marble Slabs vs. Sintered Slate: Production Process Comparison

1. Imitation Marble Slab Production Process

• Raw Material Selection: Quartz sand, resin, stone powder, ceramic powder, or cement-based composite materials.

• Texture Simulation: Reproduces marble patterns using printing, lamination, and pressing techniques.

• Surface Treatment: Polishing, glazing, or waxing enhances surface gloss and stain resistance.

The advantages of imitation marble slabs lie in their low production cost and controllable patterns, but their performance is limited by the substrate and the precision of the process.

2. Sintered Slate Production Process

• Raw Material Ratio: A scientifically formulated blend of natural mineral raw materials ensures a dense and uniform slab after sintering. • High-temperature sintering: High temperatures exceeding 1200°C fully densify the material, improving its hardness and wear resistance.

• High-pressure pressing: 10,000-ton pressure is used to create a smooth, hard slab.

• Translucent patterns: The texture runs through the slab, resisting wear and loss over time.

Sintered slabs utilize scientific processes to ensure stable performance and durability, making them a representative high-end countertop material.

Imitation marble slabs vs. sintered slabs: Performance Comparison

1. Hardness and Wear Resistance

• Imitation marble slabs: Average hardness, easily scratched by sharp knives, and may show wear marks from daily use.

• Sintered slabs: Mohs hardness of 6 or above, highly scratch-resistant, suitable for high-intensity environments.

2. High-temperature resistance

• Imitation marble slabs: Most cannot withstand prolonged high temperatures and are easily marked by hot pots or boiling water.

• Sintered slabs: High-temperature resistance exceeding 1200°C, making them safe and reliable for kitchen use.

3. Stain Resistance and Water Absorption

• Imitation Marble Slabs: Some materials are microporous and prone to color bleeding, requiring regular waxing or sealing.

• Sintered Stone Slabs: Water absorption is almost zero, resisting oil stains and sauces, making them easy to clean.

4. Service Life

• Imitation Marble Slabs: Generally last 5-10 years, depending on the substrate and maintenance.

• Sintered Stone Slabs: Lifespan can reach decades, offering excellent long-term stability.

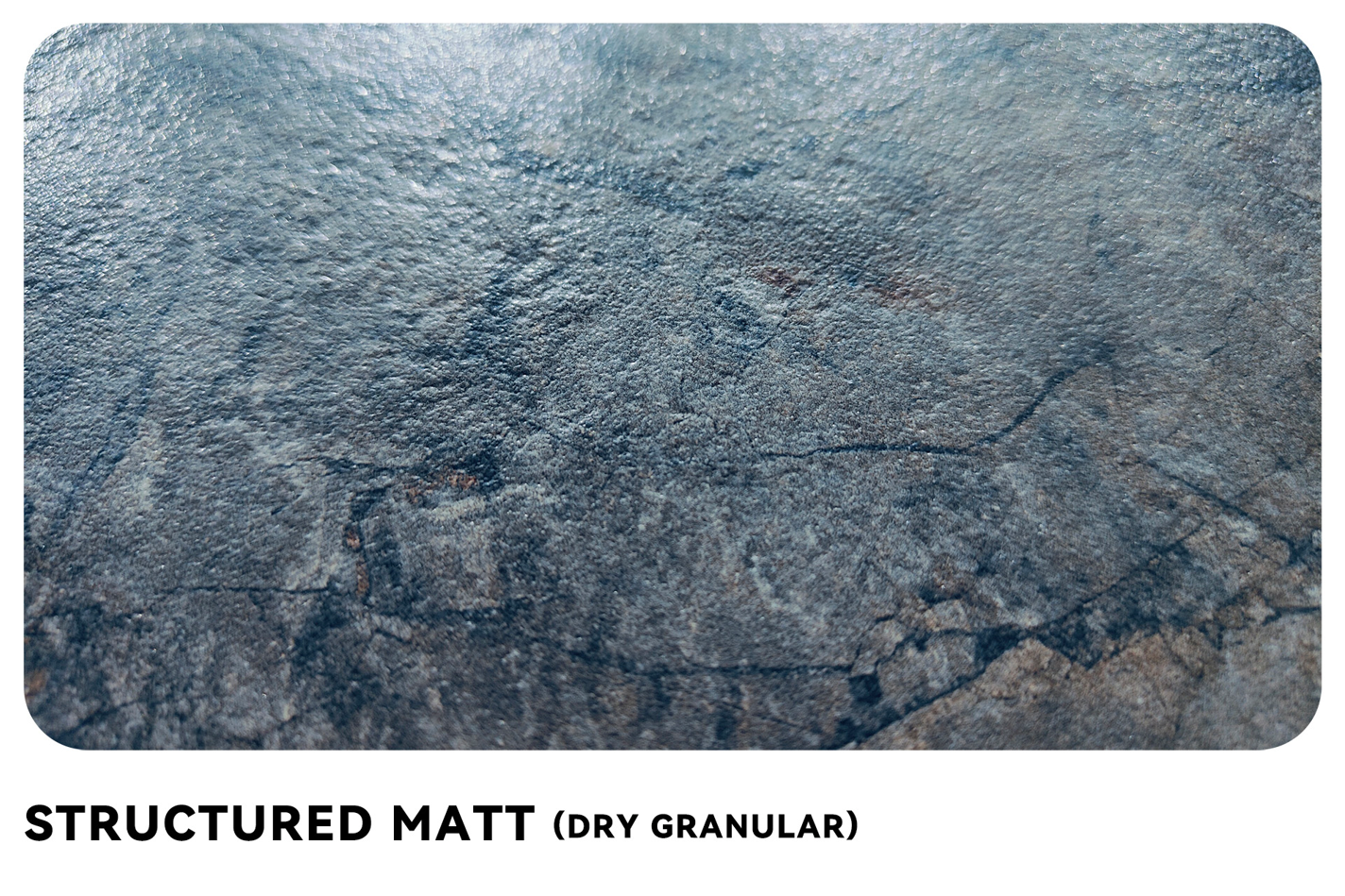

(Structured Matt Marble Sale)

Aesthetic Differences Between Imitation Marble and Sintered Stone Slabs

1. Imitation Marble Slab Aesthetics

• Highly simulates the texture of natural marble, resulting in a natural and realistic visual effect.

• Mass-produced with consistent patterns, suitable for large-scale installations.

• Low cost and affordable visual effects, but slightly inferior to natural stone in terms of gloss and depth.

2. Sintered Stone Slab Aesthetics

• Translucent texture, creating a rich, visually rich experience.

• Available in a variety of finishes, including glossy, matte, leather-like, and frosted finishes.

• It can simulate a variety of styles, including marble, wood grain, cement, and metal, offering a wide range of design possibilities.

Imitation Marble and Sintered Slate: Maintenance and Cleaning

• Imitation marble slabs require daily cleaning and waxing to prevent color bleeding and stains. Avoid strong acidic and alkaline cleaning agents.

• Sintered slabs: Requires little special maintenance; simply use water or a neutral detergent.

Imitation Marble and Sintered Slate: Application Scenarios

1. Suitable Applications for Imitation Marble Slabs

• Home accent walls and TV walls

• Commercial facades

• Limited budgets or those seeking visual impact over durability

2. Suitable Applications for Sintered Slates

• Kitchen countertops and dining tabletops

• Bathroom basins and sinks

• High-use floor coverings and public space decoration

• High-end homes and outdoor spaces

(Desert Gold Sintered Stone Slabs)

Imitation Marble and Sintered Slate: Cost-Effectiveness Analysis

• Imitation marble slabs: Affordable, visually striking, and suitable for budget-conscious renovations.

• Sintered stone: While more expensive, it offers superior durability, low maintenance, and a more cost-effective long-term performance.

Overall Conclusion: Which is better, imitation marble or sintered stone?

A comprehensive comparison:

1. If you're looking for affordability and visual appeal, and the application doesn't require high wear resistance, imitation marble is the right choice.

2. If you're looking for high durability, high-temperature resistance, wear resistance, and long-term use, and are using it in high-functionality applications like kitchens, bathrooms, and public spaces, sintered stone is undoubtedly superior.

In terms of overall performance, aesthetics, and longevity, sintered stone is superior to imitation marble and is the preferred material for high-end decoration and public spaces.

Are WOWSLAB products suitable for residential and commercial projects?

Yes, WOWSLAB marble slabs and sintered stone slabs are ideal for both residential and commercial applications. Our company from China offers eco-friendly, visually appealing, and durable products that meet high-quality standards. Buyers can purchase wholesale or single orders, request custom solutions, enjoy discounts, and benefit from competitive prices.

For high-quality marble slabs and reliable China-based suppliers, WOWSLAB is the perfect choice.